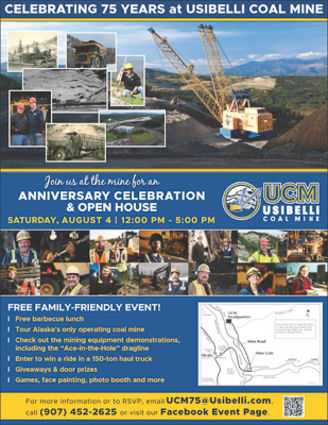

Celebrating 75 years at Usibelli Coal Mine

Alaska's only coal mine to commemorate milestone on Aug. 4 North of 60 Mining News – July 20, 2018

Last updated 9/25/2020 at 5:50am

Usibelli Coal Mine

The Usibelli Coal Mine near Healy, Alaska, produces nearly 1 million tons per year of what is considered among the cleanest burning coals mined anywhere in the world .

Celebrating its 75th anniversary this year, Usibelli Coal Mine (UCM) is Alaska's only operational coal mine. The company is proud to have an all-Alaska workforce of approximately 100 employees, of which more than one-third represent the second, third or fourth generations within their families to have worked at the mine. Today, Joe Usibelli Jr., the third generation of the Usibelli family, leads the mine as president, a position he's held since 1987. Each year UCM produces close to 1 million tons of ultra-low sulfur, sub-bituminous coal, which ranks among the cleanest burning coals produced anywhere in the world.

In commemoration of this milestone anniversary, the mine has created a special logo, is publishing a historical narrative and picture book, producing a short video and will host a celebration at the mine in Healy for employees and their families, as well as elected officials and the community, on Saturday, August 4 from 12pm to 5pm.

The mine's humble beginnings date back to 1943 when the military issued a contract to supply 10,000 tons of coal to Ladd Army Air Field, now Fort Wainwright, during World War II. The military's objective was to reduce its dependency on a single fuel source. Emil Usibelli and his friend T.E. "Thad" Sandford were among several who obtained coal leases from the U.S. Army. The company began operations with a single TD-40 bulldozer and a 1930s vintage GMC logging truck. Most coal mining at that time was done by tunneling underground. However, Emil pursued an unconventional method of pushing overburden off the coal outcrops with the bulldozer, and then pushing the exposed coal into the truck bed. This procedure was met with skepticism, but he persevered. Today, Emil's little red dozer sits in front of the UCM office and shop complex in Healy.

In 1964, Emil was tragically killed in a mining accident. His only son, Joe Usibelli took over the operation at age 25 and led the company until his retirement in 1987. He now serves as chairman of the UCM board of directors. Under Joe's leadership, the mine increased production and moved its base of operations from several mining camps in the Healy Creek Valley to the Poker Flats area in the Hoseanna Creek Valley, the same valley where mining activities continue today.

Efficiencies in engineering and production have long supported UCM's successful operations. In 1977, the mine acquired the "Ace-in-the-Hole" dragline, Alaska's largest land-mobile machine. It was transported to Healy on 26 rail cars and 40 trucks and took 11 months to assemble before starting operations in 1978.

In 1983, UCM built a new facility close to the new mining area at Poker Flats. The building included administrative offices, an engineering department, a laboratory, a maintenance area, and a logistics warehouse. Because of UCM's remote location, it is necessary for the mine to be as self-sufficient as possible. The maintenance area includes a robust machine shop, electrical shop, unit repair shop, glass shop and welding bay. The maintenance team of employees are well-trained and prepared to fabricate or modify most components utilizing modern, state-of-the-art equipment.

Nobody knows Alaska better than the people who live and work here. The mine in Healy is, quite literally, in the backyard of the people who work at UCM and their family members. It's little wonder, then, that employees feel they have a deep personal stake in protecting the quality of the land, air and water. In 1971, six years before it was required by federal law, the Usibelli family pioneered a successful reclamation program with the ultimate goal of establishing a natural landscape on previously mined land. The process includes contouring the earth and then seeding it with a carefully researched mixture of grasses and plants indigenous to the northern regions. Since 1971, over 5,500 acres of land have been reclaimed. Last year, the UCM reclamation team planted more than 25,000 trees and seeded 138 acres for final reclamation.

In 1984, UCM began exporting 750,000 tons of coal annually to South Korea through the Seward Coal Terminal at the Port of Seward, which continued through 2002. From 2003 to 2016, UCM also exported coal to Magadan in the Russian Far East, Taiwan, Japan and Chile. Since July 2016, UCM's coal export activity has paused due to unfavorable conditions in the international coal market. The Seward Coal Terminal has been placed into cold storage mode, but UCM continues to monitor global energy markets for future opportunities.

Today, UCM coal is used to fuel five Interior electric power plants – including four co-generation plants that produce steam or hot water for area heating needs, in addition to electric power. The four co-generation plants are the Fort Wainwright Central Heat and Power Plant; the Eielson Air Force Base Central Heat and Power Plant; the Aurora Energy power plant, a wholesale supplier of electricity and provider of district heat in Fairbanks; and the Atkinson Heat and Power Plant at the University of Alaska campus in Fairbanks. UCM also supplies coal for Golden Valley Electric Association, which operates Healy Units No. 1 and No. 2, adjacent to the mine site in Healy.

UCM recently completed a haul road to access a new mining area known as the Jumbo Dome Mine. This new road provides access to 83 million tons of permitted coal and has the potential to yield over 100 years of reserves at current production levels, thus sustaining UCM's operations well into the future.

UCM continually strives to improve the efficiency of both engineering and production. Last year, the mine added two new 150-ton haul trucks to its truck fleet, as well as two new 150-ton capacity coal truck boxes that increased the average haul¬ing capacity per load by 30 tons. A new coal bucket was also installed on one of the excavators that improves the overall load time into the haul trucks.

The mine has also benefited from several technology upgrades. One new practice is the use of drones, which can accurately and efficiently map and measure locations throughout the mine. The drones help eliminate potential hazards to employees, who no longer have to physically visit certain high-risk locations, such as highwalls. A new wireless equipment data system at the mine helps the maintenance department better track hours on the equipment, schedule necessary service, and more efficiently and effectively maintain the production fleet. Perhaps the most exciting recent addition to the mine's equipment is the CAT 994K wheel loader. It boasts a 35-yard cubic bucket and was assembled on site at the mine in about 30 days by CAT and UCM employees.

Since 1943, the fourth-generation family-owned busi¬ness has continued to flourish and has been a major contributor to the Interi¬or and Alaska economies. UCM wages are among the highest in the Interior and are more than twice the statewide average. UCM continues to be the largest employer in the Denali Borough and more than half of all wages earned in the community of Healy were paid to UCM employees. Indirectly, more than 400 businesses and organizations benefit from UCM's purchases of services and supplies each year. Over 95 percent of UCM's in-state spending is transacted with entities based in the Interior or Anchorage areas.

The safety of UCM employees remains one of the company's core values. Over the years, UCM has been recognized on both a state and national level for its commitment to addressing safety in all aspects of job performance. In early 2017, a new safety campaign - "Everyday Safety: At Work. At Home. At Play" - was launched to rebrand, reinforce and re-emphasize good safety practices, both on and off the job.

Coal will play a critical role in achieving our state's energy, economic and environmental goals, now and into the future. The tremendous leadership and vision from the Usibelli family, and the incredible passion and devotion of the mine's employees, have been the key ingredients of UCM's success for the last 75 years. These strengths promise to give the mine a prosperous and secure future for many decades to come.

UCM is a business in which all Alaskans can take great pride. If you find yourself in the Healy area on Saturday, August 4 – stop by and join our celebration of the mine's 75th anniversary!

Editor's Note: This column originally published in the July edition of Alaska Miner, an Alaska Miners Association publication.

Reader Comments(0)