Pentagon support accelerates Graphite One

Mining Explorers 2023 - January 18, 2024

Last updated 1/17/2024 at 11:19am

Graphite One Inc.

A rainbow touches down at the exploration camp on the world-class Graphite Creek project in western Alaska.

Graphite has not been mined in the United States for decades, which makes the nation largely beholden to China for its supply of this largest ingredient in the lithium batteries that power everything from smartphones and household appliances to electric vehicles and military hardware.

On a mission to accelerate the development of a domestic supply chain for the enormous quantities of graphite required for America's green energy and high-tech future, the U.S. Department of Defense awarded Graphite One Inc. $37.5 million to help complete a feasibility study for an advanced graphite material supply chain that will include a mine at the Graphite Creek project about 35 miles north of Nome, Alaska, and an advanced graphite processing and recycling facility in Washington state.

"This Department of Defense grant underscores our confidence in our strategy to build a 100% U.S.-based advanced graphite supply chain – from mining to refining to recycling," said Graphite One CEO Anthony Huston. "The World Bank Group reports that the production of minerals, including graphite, could increase by nearly 500% by 2050, to meet the growing demand for clean energy technologies."

While establishing a mine at Graphite Creek will provide a future domestic supply of graphite critical to the nation, it is already providing benefits to the economy of western Alaska. This is partially why Bering Straits Native Corp., the Alaska Native Claims Settlement Act (ANCSA) regional corporation for far western Alaska, made an initial US$2 million investment in Graphite One last year and has the option to invest an additional US$8.4 million in the company.

"The impressive work of the Graphite One team, which includes local BSNC shareholders, reinforces our decision to support the project," said Bering Straits Native Corp. Director of External Affairs and Public Relations Marleanna Hall. "As a BSNC shareholder originally from Nome myself, I am thrilled by what this project can do for our region."

Strategically important graphite

The rapid transition to low-carbon energy and transportation is powering skyrocketing demand for new sources of graphite and the capacity to upgrade this raw material into the coated spherical anode material that is the single largest ingredient in lithium-ion batteries.

Upon completion of an in-depth assessment of minerals critical to America's clean energy transition, U.S. Energy Department forecasts that global graphite demand could be more than eight times current production by 2035.

China, however, accounts for more than 60% of graphite mined globally and nearly 90% of advanced anode material production.

"As the United States and the world transition to an era of dramatically increased mineral use, it is crucial for us to rebuild our domestic supply chains-especially for natural graphite, which we have not produced for more than 30 years and currently depend on China and other nations for the entirety of our supply," said Sen. Lisa Murkowski, R-Alaska.

Graphite One's plans to build a domestic graphite supply chain became even more critical upon China's December implementation of state-controlled restrictions on the exports of nine types of high-purity and high-density artificial graphite, natural flake graphite, and related products.

"The Graphite One project is in a league of its own, in terms of the scope of the resource in the ground in Alaska and the vision the company has for manufacturing anode materials and recycling batteries in Washington state," Murkowski continued.

Matching world-class size with demand

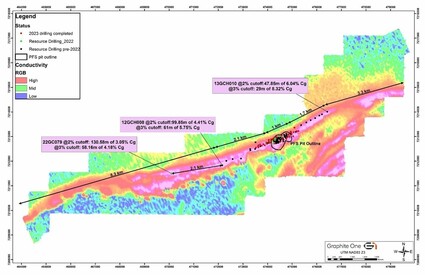

Graphite One has already outlined more than 14 million metric tons of graphite at Graphite Creek, and this only accounts for a roughly three-mile subsection of a more than 10-mile-trend of graphite that has been traced across the Graphite Creek property.

According to a calculation completed in early 2023, Graphite Creek hosts 37.6 million metric tons of measured and indicated resources averaging 5.15% (1.9 million metric tons) graphite; plus 243.7 million metric tons of inferred resource averaging 5.14% (12.3 million metric tons) graphite.

A 2022 prefeasibility study for Graphite Creek envisioned a vertically integrated graphite supply chain that includes a mine that would produce an average of 51,813 metric tons of graphite concentrate per year and a processing and recycling facility in Washington that would upgrade the concentrates into 49,600 metric tons of spherical coated graphite that serves as the anode material in lithium-ion batteries and 25,400 metric tons of other advanced graphite products per year.

North American automakers and the U.S. government, however, want to see a Graphite One supply chain that better matches Graphite Creek's world-class potential to meet the rocketing demand being driven by the transition to EVs powered by clean energy.

To meet the higher bar set by future buyers of the advanced graphite products its vertically integrated supply chain will produce, Graphite One is now focused on building enough measured and indicated resources to support a substantially larger mine at Graphite Creek.

"(T)he continued expansion of our Graphite Creek resource will support our plan to quadruple the annual production from our PFS study," said Graphite One Senior Vice President of Mining Mike Schaffner.

Expanding the resource

An 8,736-meter drill program carried out in 2023 focused on upgrading and expanding the deposit, as well as collecting geotechnical and hydrological data for the feasibility study.

Highlights from 52 resource upgrade and expansion holes drilled last year include:

• 9.6 meters averaging 13.19% graphitic carbon in hole 23GC088.

• Nine meters averaging 14.89% graphitic carbon in hole 23GC092.

• 15.2 meters averaging 10.75% graphitic carbon in hole 23GC099.

• 10.88 meters averaging 11.14% graphitic carbon in hole 23GC102.

"The results – 52 graphite intercepts over 52 holes – confirm our confidence that Graphite Creek is truly a generational resource of strategic value to the United States, and we wish to thank the Alaskan Government, our funding partners, local stakeholders, and communities for their continued support in advancing this critical asset," said Huston.

The feasibility study that details a larger mine at Graphite Creek and a processing plant in Washington is expected to be completed by the end of this year.

Reader Comments(0)